Industrial AI Unpacked: Introducing a new series of Articles and Podcasts on AI

Our no-nonsense look at how AI is reshaping the bridge between digital twins and real-world operations.

“We don’t want to make the same bad decision from today faster — we want better decisions.”

That’s what Zev Arnold told David in the podcast we published in August.

And it hit a nerve.

The pandemic showed how much we depend on goods made around the world, and how brittle that network can be. Global tensions between superpowers are flaring up and hurting the same companies they try to save. The silver tsunami means everybody is facing the loss of experts, and replacing them is getting harder. And on top of that costs keep rising…

But this is not a “wait and see” situation.

We simply don’t have that luxury.

It feels like ages ago when ChatGPT first appeared

(and with it, the start of the “AI washing” wave).

Remember all those early claims?

The vendors promised to solve everything, transform the world, while in reality they simply rebranded a linear regression… or even remote workers somewhere far away pretending to be “the AI”?

Fast forward to today and the AI hype train is going as fast as ever: Agents, MCP, and the usual “but this time it’s really different” promises.

Well…

If there’s something strange

In your neighborhood

Who you gonna call?

(The IT/OT Insider is the correct answer 😀)

Late last year, we found ourselves in a similar spot with Industrial DataOps: lots of questions, plenty of conflicting answers. Our solution then was to create a Capability Map and a dedicated podcast series on Industrial Data. It forced us to do the thinking, cut through the noise, and bring clarity.

And when it comes to Industrial AI, we are going to do exactly the same! 🎉

Today, we’re announcing our new series: Industrial AI Unpacked.

Our goal is to give you the frameworks and industry insights you need to think clearly about AI. Whether you’re an end user looking to make real step changes in how you operate, or a vendor trying to position yourself in a market full of buzz, this series is for you.

So before we continue, if you aren’t subscribed yet: this is your moment!

A different look at Industrial Digitalization

If you have been following us for some time, you know we always try to find a new way to tell a story. To explain you how AI fits into industrial operations today, and how it should evolve, we’ll start with a short historical detour 🙂

Ever since the invention of microcircuits in the 1960s, industrial digitalization has had one primary goal: help people work more effectively in the physical world.

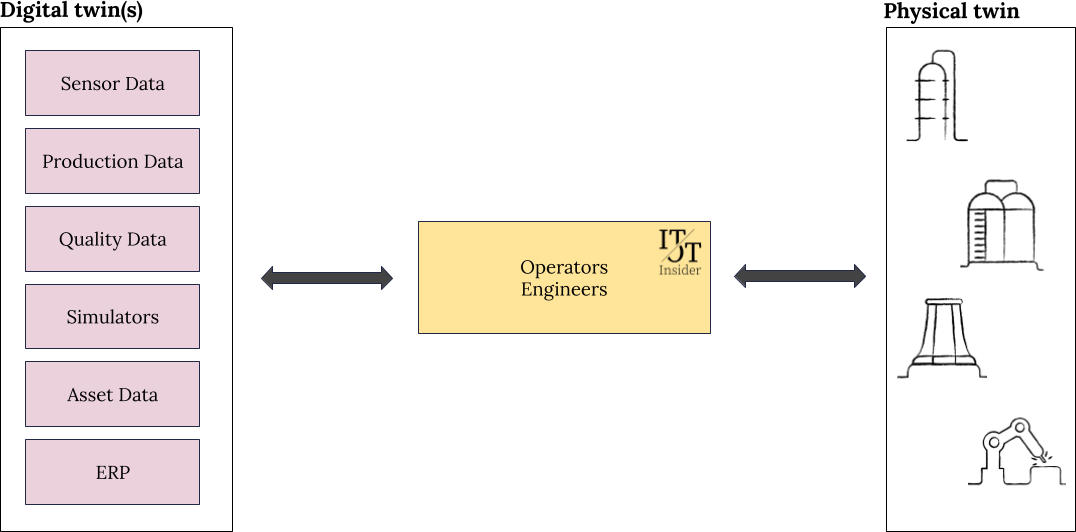

The Physical vs Digital Twin(s)

The Physical Twin is the real production facility — where the cars are assembled, the chemicals refined, the water purified. It’s where sunlight, wind, gas, or water gets transformed into electricity. This is where value is physically created, and where the laws of physics dictate that there’s no “undo” button.

Then there’s the digital layer. Operator rooms full of screens showing real-time process data. Plant managers and engineers making decisions based on reports from various systems. Parameters being tuned based on sensor readings. We call these Digital Twins — though the truth is, you don’t have one twin, you have many. They just never tell you that part.

Life Between Two Worlds

Industrial operations live with one foot in each world.

In the digital world, anything can be imagined, modeled, or reconfigured instantly. In the physical world, you can’t just hit Ctrl+Z if the reactor explodes.

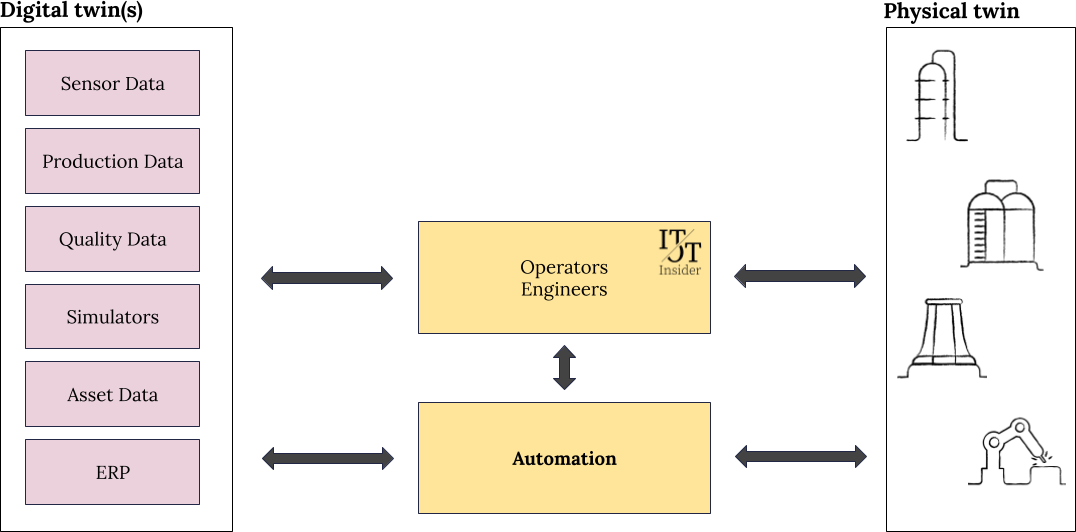

Yes, automation exists and in some cases, plants are remotely managed, even “lights out,” with robots doing work and control systems making millisecond decisions. But here’s the catch:

Automation that directly interacts with physical reality only happens where the outcome is predictable.

Think about it: how would IT work if every time you ran a program, it behaved differently or even wiped your disk? You’d build in checks, limit what the program can do, and have safeguards everywhere. That’s exactly how industrial automation is designed.

We automate where things are deterministic, where inputs reliably lead to the same outputs.

We don’t automate where they are non-deterministic, because safety and the irreversibility of physical reality demand human oversight.

For everything outside the deterministic zone, we still rely on the middle layer in our diagram: the engineers, shift operators, maintenance crews, and quality experts who keep the plant running.

Once you burn a multi-million-dollar high-voltage transformer, there’s no rollback.

So What Changes with AI?

Everything!

Just kidding… not really.

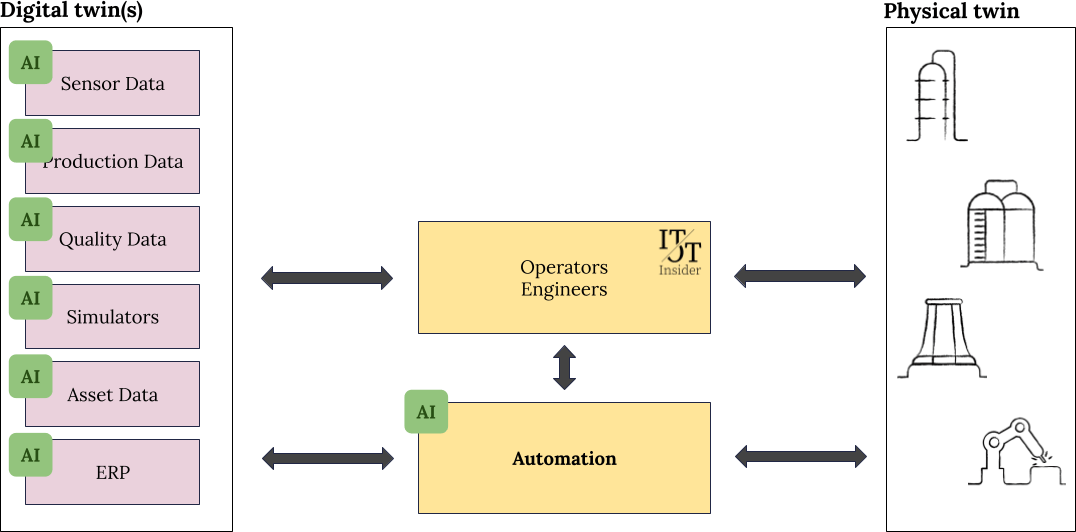

Today, AI is more of an add-on than a replacement.

Of course, both the Classical Predictive AI as well as Generative AI can help to unlock data from the digital twins better and faster: from analyzing pump maintenance history, to checking sensor data, to verifying spare parts inventory, to triggering a maintenance check, to helping with coding.

But this is not really the step change we are looking for. Because the interactions between the digital and physical world remain largely unchanged.

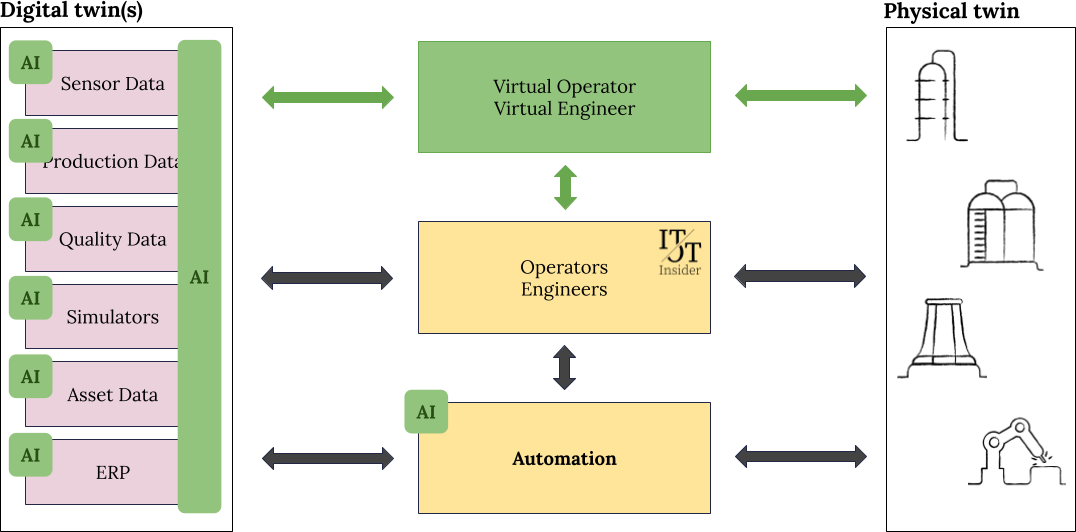

Towards a fully embedded Virtual Operator and Engineer

Enter the Virtual Operator and Engineer: not robots on the shop floor, but AI agents embedded in the digital layer. Their job? Orchestrate across systems, surface the right information, and cut the friction between digital and physical worlds.

This isn’t about replacing people.

The automation layer stays.

Safety systems stay.

Operators and engineers stay.

What changes is that they get augmented.

Think of a colleague who never forgets where the HAZOP file is, knows which pump failed last winter, and checks whether the spare part in stock is actually compatible.

The quantum leap is that AI can begin handling decisions in the gray, non-deterministic zones. Not all decisions, not everywhere — but some. At first, agents only advise. Then they earn the right to tweak parameters. Later, they’ll get limited authority to act, still under mechanical checks and human overrides. Just like self-driving cars, this won’t be “off” to “on” in three years. It’ll be gradual, with trust built step by step.

Examples? Automated HAZOP scans. Labor scheduling. Anomaly detection across sensors. Multi-agent teams negotiating the best course of action.

And here’s the key: you don’t need perfect data, flawless architectures, or the ultimate contextual model to start. Industrial AI is more like mining gold — the ore is messy, but if you’ve got a repeatable way to refine, you can create real value. Start with the use case, refine as you go, and let the rest follow.

What we have planned

This is just the beginning. To make sense of Industrial AI, we first need to cut through the noise and get clear on what it actually means. That starts with the basics: the difference between Predictive AI, Generative AI, and the now-trending Agentic stuff. Each has its place, its strengths, and its limitations. This deserves its own spotlight — and it’s exactly what we’ll cover in next week’s article.

Beyond that, we’ll bring you interviews with end users, experts, and vendors, so we can go deeper together and share lessons straight from the field.

Because when strange things start running through your head…

Who you gonna call?

(Ghostbusters, sure — but in our world, it’s the IT/OT Insider 😀)

Call for input

Our industrial AI series will include articles and podcasts with some of the content already part of the current ITOT.Academy cohorts. If you think you have something interesting to add to the discussion, let us know. Please keep in mind that we always prefer end-user stories over vendor interviews. Later this year we will also release a listing of Industrial AI providers, similar to the one we published and updated in our Industrial Data Platform Capability Map.