Beyond the Blog: What six months of IT/OT exploration taught us about industry challenges (Part 1)

We share some of our learnings: You are not alone, Outdated ways of working are holding digital transformation back, there is a perception problem and more...

We have been writing articles now for over 6 months and honestly: doing so really helped us understand the world we live and work in much better. Our most important learnings?

Literally every company is facing the same challenges around scaling Industry X.0 initiatives. You are not alone ;)

We have enough technology available. What is holding us back is outdated ways of working.

Everything you do should be focussed on making data access as easy as possible for every user and application while keeping your technical debt under control.

There is a perception problem that only ‘IT’ is able to build data platforms and OT’s job is ‘just to give them some data’. This mindset is totally wrong, one-sided and will only lead to divergence and thus to a failed digital transformation program.

Data engineers are becoming a new bottleneck in your organization’s data ambitions: it’s happening right in front of us and we are not seeing it.

About last week

Last week I (David) had the absolute pleasure and privilege to do a keynote presentation in Malmö, Sweden.

This was the perfect time to test out some of our concepts as the audience primarily consisted of professionals working in the OT world. Presenting something on stage always helps me twofold: (1) it forces me beforehand to find a common thread and to grasp the essence and (2) the feedback provided by the audience afterwards is even more valuable as it either validates what I’ve said or provides new insights.

One thing I heard numerous times is:

We thought we were the only ones facing these issues around bringing together IT and OT, but we now understand that everyone in the industry is facing more or less the same.

Yes! It’s a fact that almost all of us working in manufacturing, critical infrastructure and similar sectors are struggling with this thing called “IT/OT Convergence”. I’d like to take the opportunity to summarize some key learnings and new insights in this and the next post.

The Great Unlock

The longer I think about what we are doing, the more I’m convinced that IT/OT Convergence is nothing more or less than enabling Data Convergence. Making data available in an understandable, qualitative, unified and scalable way to everyone who needs to somehow ‘do their job’ using it. Or otherwise said: allowing to Scale your Data Driven Culture.

Why is predictive maintenance so hard? Because maintenance technicians don’t want to spend hours digging through Excel sheets. When the buzzword was “Augmented Reality”, we were not looking for ways to draw something in 3D (the gaming industry is way more advanced than the stuff we were building). No, we needed to integrate several data sources into one application and that’s exactly what was holding us back. Same now for Artificial Intelligence: the algorithms are not the problem, the data is.

IT/OT Convergence ➡️ Data Convergence ➡️ Scale Data Driven Culture

When we want our company to have a data driven culture, we need to combine the technology and agility found in IT, with the stability and process knowledge found in OT. We need to step away from single ‘point’ solutions, infinite Proof of Concepts and (data) engineers being the bottleneck for every single use case and move towards scalable and secure data access. That is “The Great Unlock”: making sure we don’t waste time building new interfaces, extracting and cleaning data, inventing hot water over and over again !

Anti-pattern 1: The business did not answer the WHY

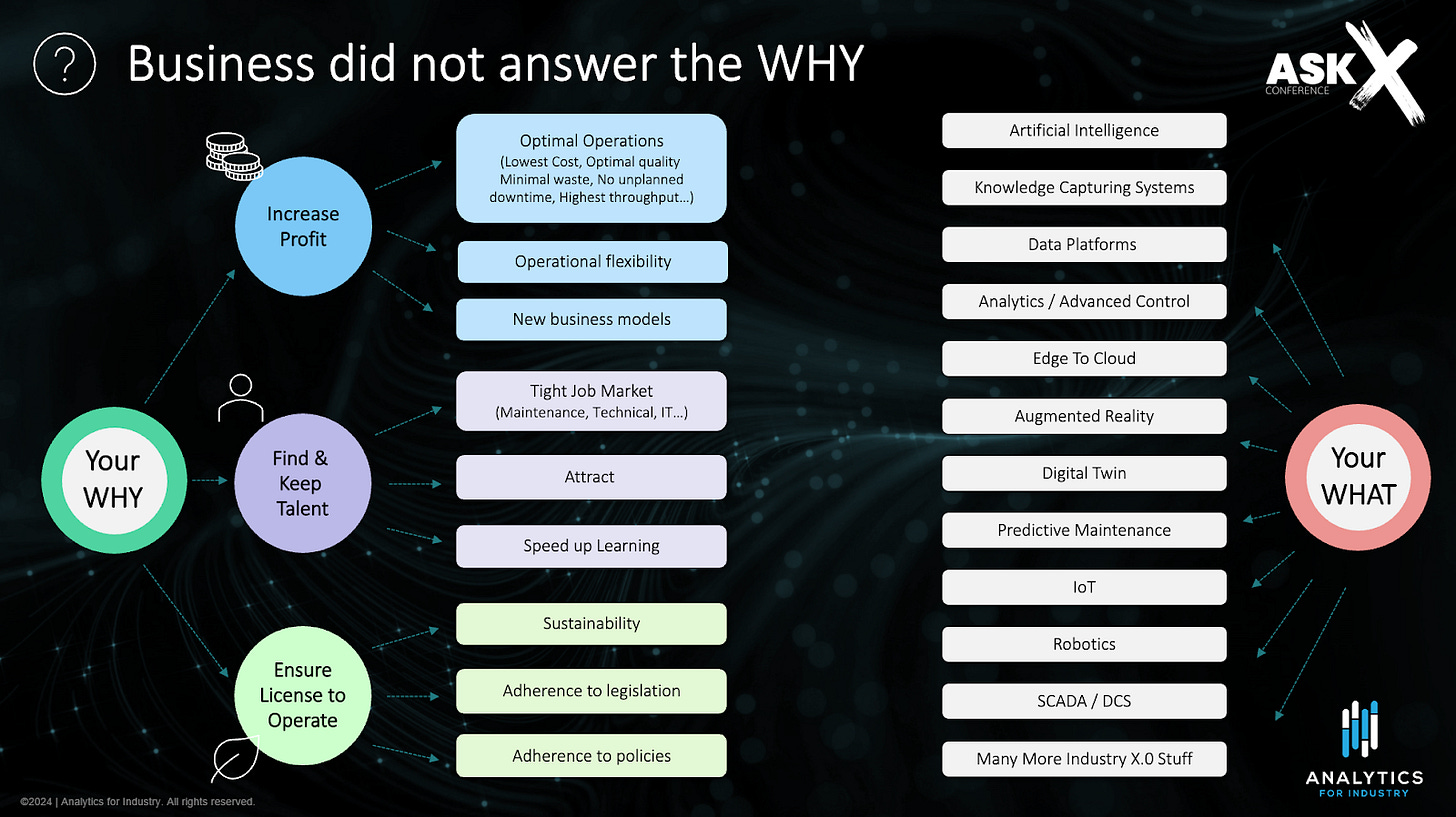

Most people love to talk about tech (the WHAT), but technology is not really a bottleneck. As we discussed in our article Why your Why matters, your business lives on the left side of the image below, in their ‘WHY’: digitalization should be an answer to Increasing Profit, Finding & Keeping Talent and Ensuring License to Operate. When the why is not answered, the WHAT will almost always fail (no budget, no resources, no management attention, wrong scoping)...

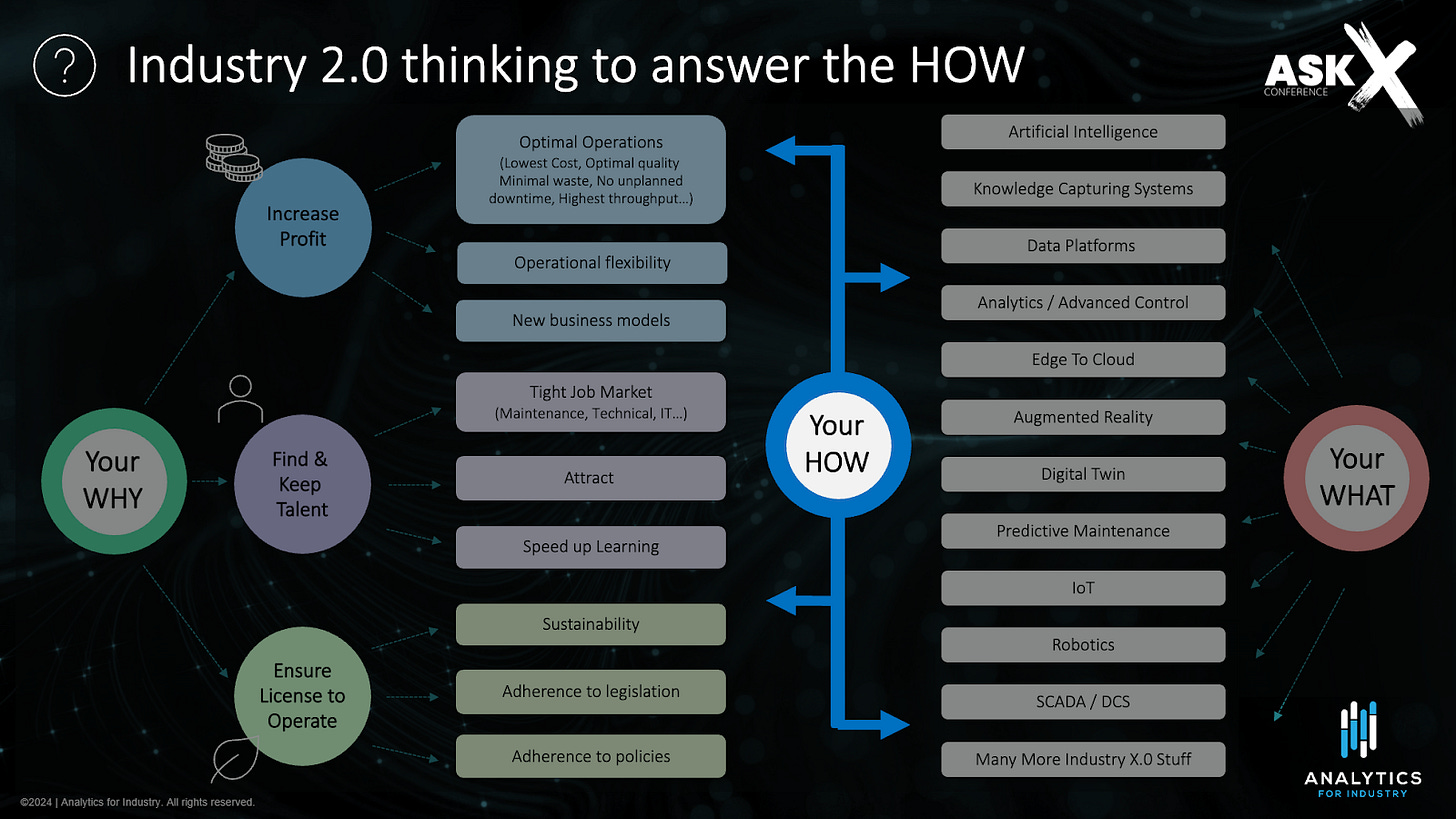

However, even when your WHY is answered, and your WHAT is carefully selected. You can still end up doing endless PoC’s, writing 100’s of pages of user requirements or finding yourself stuck in countless management meetings. This is where your HOW comes in…

Anti-pattern 2: We apply Industry 2.0 thinking to answer the HOW

Face it: most people in OT have a technical/engineering background. They are really good at solving well defined problems, preferably with minimal impact on operations. If needed, we implement a quick fix which we - hopefully - will replace during a next plant shutdown or systems migration. Our managers are also good in running a plant and they are experts in working in a CAPEX driven world. We call this ‘applying Industry 2.0 thinking’ which we covered in several articles: Should we introduce Agile Ways of Working in IT/OT?, The real reason manufacturing digitalization fails and Are you still managing the “Henry Ford”-way?.

We need to step away from applying this risk averse mindset to digitalization projects for one simple reason: in most cases you don’t know in advance how you will be solving a particular problem:

You will encounter stuff you can’t solve and need to stop (fail fast).

You will try something which is not working and need to pivot to a completely different solution (fail forward).

Your organization, management and peers need to understand that psychological safety is of paramount importance (feeling safe and supported even when stuff is not going as planned).

When you are feeling safe, the next step is to increase your Flow of Work, meaning: focus on enablers, remove bottlenecks, remove technical debt etc…

Answering the How is a cultural thing.

It’s the glue.

It makes or breaks everything.

So much has been said and written about this in the IT world, we highly recommend that you check out our IT/OT Book Library and start reading books such as The Phoenix Project (I actually gave 2 copies away during my presentation in Malmö 😀)

Just a thought:

The origins of Lean manufacturing, stemming from the Toyota Production System in post-war Japan, introduced efficiencies and continuous improvement principles that later influenced Agile and DevOps methodologies, emphasizing flexibility, feedback, and iterative development. However, for our own digital transformation we kind of missed to apply those principles ourselves, isn’t that ironic?

More coming next week!

In Part 2 of this article, I will share some new thoughts on other topics such as enforcing IT/OT Convergence, the Data Journey and the pivotal role IT/Data Engineering is playing today, also when working with sensor data. Make sure to subscribe :)